TL;DR — quick picks

- Choose synthetic rubber when you need higher thermal stability and better resistance to oils/fuels/ozone/UV (e.g., FKM, EPDM, NBR), or when a specific environment demands a tailored polymer.

- Choose natural rubber (NR) when you need top tear/fatigue resistance, high elasticity, and good tack/adhesion (e.g., many tire and vibration applications)—provided ozone/UV and fluids are managed.

What are we comparing—and why it matters

- Natural rubber (NR): tapped latex from Hevea brasiliensis; predominantly cis-1,4-polyisoprene; excellent elasticity and fatigue resistance but inherently sensitive to ozone/UV unless protected.

- Synthetic rubber (SR): elastomers polymerized from petroleum-derived monomers (e.g., SBR, NBR, EPDM, FKM). Families are engineered for thermal/chemical/weathering profiles beyond typical NR performance.

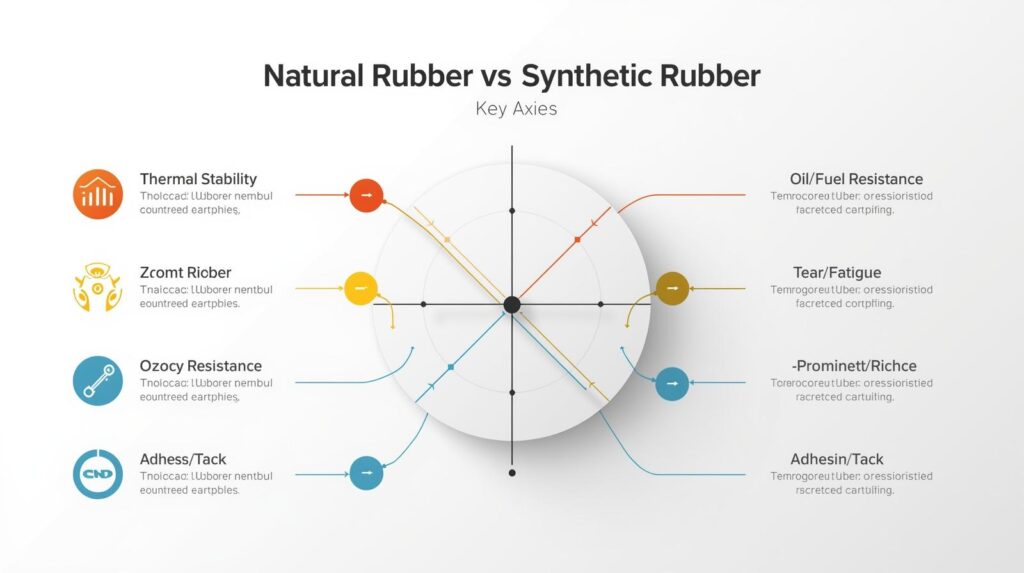

Property-by-property comparison (what changes in practice)

| Property | Natural Rubber (NR) | Synthetic Rubber (examples) | Why it matters |

|---|---|---|---|

| Thermal stability | Moderate; heat aging needs careful compounding | Often superior; e.g., FKM for high heat | Under-hood, process lines, high-temp seals. |

| Oil/fuel/solvent resistance | Limited without special compounding | NBR, FKM excel vs hydrocarbons | Fuel systems, oil-wet seals. |

| Ozone/UV/weathering | Inherently sensitive; needs antiozonants/waxes | EPDM, FKM are much more resistant | Outdoor/weather seals, roofing. |

| Tear/fatigue/elasticity | Excellent; high resilience; good tack/adhesion | Ranges from moderate to excellent by family | Tires, vibration control, dynamic flex parts. |

| Adhesion/tack | Naturally tacky; bonds to cords, fabrics well | Varies; often needs primers/adhesives | Belting, tires, reinforced parts. |

GMT also presents a coarse comparison table (hardness, temp bands, abrasion, oils) and notes “it depends on application,” which is correct but needs context; families within “synthetic” vary widely.

Use-case map (examples)

- Automotive/tires & mounts → NR/SBR blends for treads & carcasses; NR for dynamic fatigue; FKM/NBR for hot, oil-contact seals.

- Seals, gaskets, hoses → NBR (oils), FKM (high temp + chemicals), EPDM (steam/weather/water), NR only where fluids & ozone are controlled.

- Outdoor/weather → EPDM for ozone/UV; NR requires protection/additives if used outdoors.

- Electrical/insulation → Several SR families (e.g., silicone, EPDM) are favored; selection depends on dielectric & temperature.

Breiner’s article echoes that NR excels in tear/fatigue and tack (tires), while SR shines in chemicals/temperature/ozone—useful rules of thumb for first pass selection.

Cost & supply (why prices move)

- NR pricing is tied to agricultural supply (yield, weather, planting cycles), which adds volatility and regional dependency. SR tracks petrochemical feedstocks and energy pricing; both move with demand (e.g., automotive). GMT summarizes these drivers at a high level.

- Brand content (e.g., Yulex) emphasizes long-term renewability of NR but acknowledges price swings for both NR/SR. Treat price tables online as indicative only; always confirm current quotes.

Environment & health

- NR is renewable (trees tapped for many years) and biodegrades faster than most SRs; however, allergy risks exist for natural latex and must be managed in some uses. (Yulex advocates plant-based choices; keep brand lens in mind.)

- SR is typically petroleum-derived and more durable outdoors/chemically, which can extend service life; not inherently biodegradable, but recycling/energy recovery pathways exist. Ozone/UV resistance in many SRs reduces cracking versus NR.

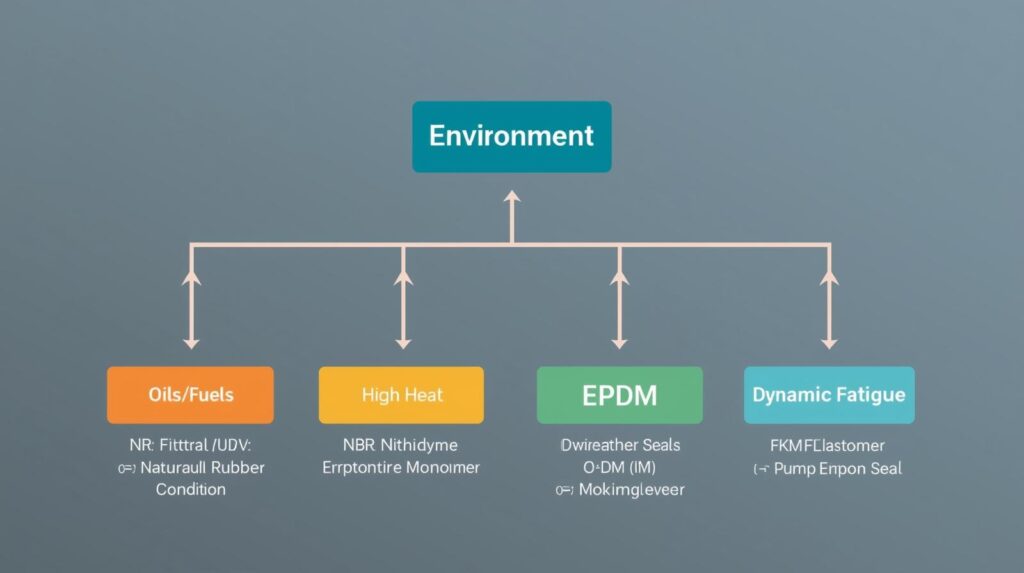

Selection workflow (copy/paste)

- Profile your environment: fluids/chemicals, continuous & peak temperature, ozone/UV, washdowns, steam.

- Define mechanics: target hardness & tensile (e.g., verify with standard methods), expected fatigue/tear demands, compression set window.

- Short-list families:

- Oils/fuels → NBR, FKM

- Ozone/UV/weather/steam → EPDM (or silicone for temperature extremes)

- High tear/fatigue, tack → NR (with ozone protection)

- Validate with testing (request supplier data to recognized methods such as tensile & hardness): ask for recent COA/test sheets and in-application trials when stakes are high.

- Balance cost & sustainability: evaluate life-cycle (durability vs replacements), supply risk, and recycling options relevant to your industry.

(Standards are application-specific; this article focuses on comparison and selection—ask suppliers for the exact methods they used when reporting tensile, hardness, compression set, and aging data.)

FAQ

Is synthetic rubber always better than natural rubber?

No—SR often wins on thermal/chemical/ozone resistance, but NR can outperform in tear/fatigue/elasticity and tack—vital in dynamic, reinforced goods. Match to environment and load.

What synthetic rubber should I use outdoors?

EPDM is a mainstay for ozone/UV/weather; consider FKM for high-temp/chemical outdoor service.

Why is NR common in tires?

Its fatigue resistance, resilience, and tack for cord adhesion remain hard to beat; SRs are blended for specific properties.

Which is more sustainable—NR or SR?

NR is renewable and generally more biodegradable; SR durability can reduce replacements in harsh conditions. Consider the full life-cycle for your use.

Do prices differ a lot?

Yes. NR tracks agriculture; SR tracks petrochemicals. Both move with automotive/industrial demand; confirm current quotes.